astm for hardness testing|astm rockwell hardness chart : maker We would like to show you a description here but the site won’t allow us.

Resultado da 3 dias atrás · 4.376 inches Height. Dual-slot Width. Thermal and Power Specs: 97 C Maximum GPU Tempurature (in C) 140 W Maximum Graphics Card Power (W)

{plog:ftitle_list}

7 de jan. de 2023 · MOOMOO.io. Enter Game. Servers. Select Color. How To Play. Collect resources around the map to build a village. Your Windmills generate gold over time. But make sure to protect them from other players. Controls.

Using test methods such as scanning electron microscopy, hole-drilling strain-gage method, semiautomatic and automatic image analysis, and X-ray diffraction, parameters like elastic moduli, impact strength, ductility, hardness, residual stress, and grain size are measured. Listed below are common American Society for Testing and Materials (ASTM) .

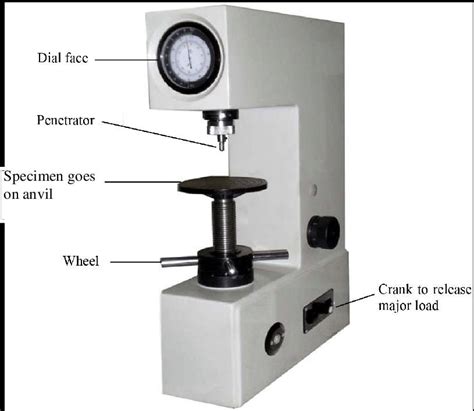

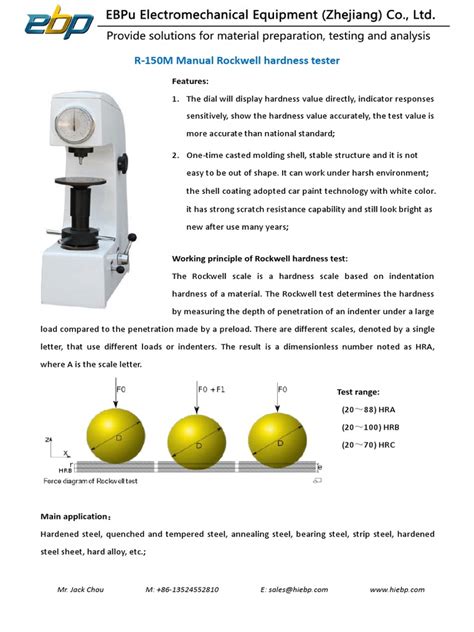

well hardness test blocks. The standardizing machine differs from a regular Rockwell hardness testing machine by having tighter tolerances on certain parameters. 3.1.7.3 portable Rockwell hardness testing machine a Rockwell hardness testing machine that is designed to be transported, carried, set up, and operated by the users, and thatThis post references the ASTM Rockwell hardness standard test and will teach you all you need to know. I. Significance of Rockwell Hardness Standard Test. To correlate the wear and resistance, tensile strength, elasticity, and other physical characteristics of metallic materials, the Rockwell Hardness Test, an empirical hardness test, is used. .

5.3 Because microindentation hardness tests will reveal hardness variations that commonly exist within most materials, a single test value may not be representative of the bulk hardness. Vickers tests at 1000 gf can be utilized for determination of the bulk hardness, but, as for any hardness test, it is recommended that a number of indents are made and the average .We would like to show you a description here but the site won’t allow us.

ASTM E18 is the industry standard for Rockwell hardness testing of metallic materials. This specification includes both theory and standard practice statements. For those companies Nadcap accredited in heat treat where the AC7102/5 for hardness and conductivity testing is included, an additional layer of requirements come into play. ASTM E384: This standard is for hardness testing on a micro-scale, and therefore includes the Vickers and Knoop hardness tests. ISO 6506: This standard mirrors ASTM E10, as it contains the standard method for measuring the Brinell hardness of metals.

1.3 The portable hardness testers covered by this test method are verified only by the indirect verification method. Although the portable hardness testers are designed to employ the same test conditions as those defined in the standard test methods, the forces applied by the portable Rockwell and Brinell testers and the depth measuring systems of the portable .

ASTM E 18-07 Standard Test Methods for Rockwell Hardness of Metallic Materials is the active and current standard by which Rockwell Hardness Testing is performed, and is also the most frequently used hardness testing method. Standard Test Method for Film Hardness by Pencil Test D3363-22 ASTM|D3363-22|en-US Standard Test Method for Film Hardness by Pencil Test Standard D3363 Standard Test Method for Film Hardness by Pencil Test> new BOS Vol. 06.01 Committee D01 $ 61.00 In stock Significance and Use.The ASTM E92 standard, developed by ASTM International—an organization known for their global standards—specifies a standardized method for Vickers hardness testing.This method is essential for the assessment of the wear resistance and durability of materials, which directly influences the performance and service life of the products for which they are used.Hardness testing within the realm of materials testing. Today, hardness testing is one of the most widely used methods in mechanical materials testing, especially for metals. On the one hand, this test method can be used to find qualitative relations to other material properties (e.g., strength, stiffness, density) or to the material behavior under certain stresses (e.g., abrasion .

1.5 At the time the Brinell hardness test was developed, the force levels were specified in units of kilograms-force (kgf). Although this standard specifies the unit of force in the International System of Units (SI) as the Newton (N), because of the historical precedent and continued common usage of kgf units, force values in kgf units are provided for information .

refractometer ethanol and water

rockwell hardness testing procedure pdf

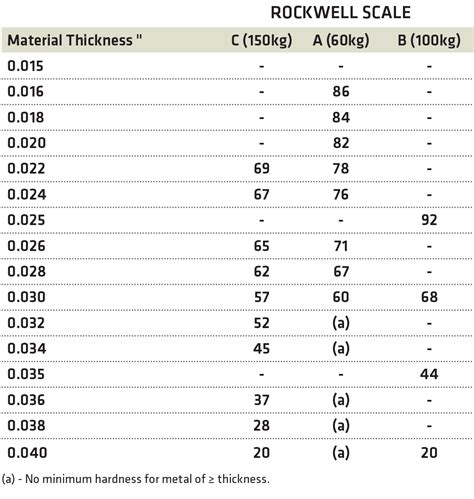

test: the Rockwell hardness test and the Rockwell superficial hardness test. The significant difference between the two test classifications is in the test forces that are used. For the Rockwell hardness test, the preliminary test force is 10 kgf (98 N) and the total test forces are 60 kgf (589 N), 100 kgf (981 N), and 150 kgf (1471 N).The hardness of rubber and elastomers according to Shore is determined using test procedures standardized in compliance with ISO 48-4 or ASTM D2240.. In the Shore hardness test, the indentation depth is measured using a spring-loaded indenter made of hardened steel to indent the material/specimen.The indentation depth is a measurement for Shore hardness, that is .

finished to commercial mill standards for hardness testing, covering the entire range of these alloys from their annealed to their heavily cold-worked or age-hardened conditions, includ- . ASTM test methods: 3.1.1 Vickers Hardness—Test Method E92. 3.1.2 Brinell Hardness—Test Method E10. 3.1.3 Rockwell Hardness—Test Method E18Scales A .Rockwell Hardness ASTM D785, ISO 2039; Sample Preparation - Machining; Sample Preparation - Molding, Conditioning; Shear Strength and Modulus - Core ASTM C393; Shear Test ASTM D732; Shear Test (Core) Tension or Compression ASTM C273; Shore Hardness (Durometer) ASTM D2240; Short Beam Shear ASTM D2344; Specific Gravity/Density ASTM .ASTM International standards E 10, Test Method for Brinell Hardness of Metallic Materials, and E 18, Test Methods for Rockwell Hardness of Metallic Materials, have both recently undergone extensive revisions.Both standards are under the jurisdiction of Subcommittee E28.06 on Indentation Hardness Testing, which is part of ASTM International Committee E28 on .

1.5 Units— At the time the Rockwell hardness test was developed, the force levels were specified in units of kilograms-force (kgf) and the indenter ball diameters were specified in units of inches (in.). This standard specifies the units of force and length in the International System of Units (SI); that is, force in Newtons (N) and length in millimeters (mm).

ACKNOWLEDGMENTS Theauthorwouldliketothankthefollowingpersonsforsharingtheir experienceandprovidinginformationforthisGuide.Theirinputandreview .II. Principles of Vickers Hardness Test. The general principle of the Vickers hardness test, defined by ASTM E-384, is based on an optical measurement system. The Vickers hardness test can be a micro indentation test and also for the macro hardness test. It is .2.1 ASTM Standards:2 A394 Specification for Steel Transmission Tower Bolts, Zinc-Coated and Bare E4 Practices for Force Verification of Testing Machines E8/E8M Test Methods for Tension Testing of Metallic Ma-terials E10 Test Method for Brinell Hardness of Metallic Materials E18 Test Methods for Rockwell Hardness of Metallic Ma-terials

Standard Test Method for Leeb Hardness Testing of Steel Products A0956_A0956M-22 ASTM|A0956_A0956M-22|en-US Standard Test Method for Leeb Hardness Testing of Steel Products Standard A956/A956M Standard Test Method for Leeb Hardness Testing of Steel Products> new BOS Vol. 01.03 Committee A01 $ 76.00 In stock The Brinell hardness test identifies the indentation hardness of a desired material. Guidelines for Brinell testing machines and the procedures for performing Brinell hardness tests are standardized through ASTM E10-23: Standard Test Method for Brinell Hardness of Metallic Materials. What Is a Brinell Hardness Test?

possible to differentiate between hardness due to calcium ions and that due to magnesium ions by this test method. 1.2 This test method was tested on reagent water only. It is the userÕs responsibility to ensure the validity of the test method for waters of untested matrices. 1.3 The values stated in SI units are to be regarded as standard.

Note 1: The Vickers and Knoop hardness numbers were originally defined in terms of the test force in kilogram-force (kgf) and the surface area or projected area in millimetres squared (mm 2).Today, the hardness numbers are internationally defined in terms of SI units, that is, the test force in Newtons (N). However, in practice, the most commonly used force .1 This test method is under the jurisdiction of ASTM Committee E-28 on Mechanical Testing and is the direct responsibility of Subcommittee E28.06 on Indentation Hardness Testing. . of the Macro-Rockwell hardness test is illustrated in Fig. 1 and defined in Table 2. 7.8 After each change, or removal and replacement, of the

rockwell hardness testing guide pdf

The new standard, A 1038, Practice for Portable Hardness Testing by the Ultrasonic Contact Impedance Method, is under the jurisdiction of ASTM Subcommittee A01.06 on Steel Forgings and Billets. "The solution is to take the hardness tester to the forging rather than the other way around," says Ed Nisbett, an independent consultant who is .

refractometer ethanol correction

WEBTạo portfolio độc đáo và độc nhất với giao diện mẫu đẹp mắt trên Tempi. Thể hiện sự cá nhân hóa của bạn và gây ấn tượng đặc biệt với khách hàng.

astm for hardness testing|astm rockwell hardness chart